Two Years of EU4MOFs: Progress Across the Working Groups

Over the past two years, the EU4MOFs COST Action (CA22147) has made significant progress toward its overarching goal of improving the reproducibility, scalability, and technological impact of metal–organic frameworks (MOFs). Through the coordinated efforts of five Working Groups (WGs), the Action has strengthened collaboration across disciplines, advanced standardisation efforts, engaged industry partners, and supported the next generation of MOF researchers. Below, we highlight recent progress and key achievements across all WGs.

WG1 – MOF Synthetic Protocols and Optimisation

WG1 has focused on addressing one of the core challenges in MOF research: reproducibility. A major achievement has been the initiation of coordinated interlaboratory Round Robin Tests (RRTs). In Round Robin Test 1 (RRT1), more than 30 laboratories worldwide synthesized benchmark MOFs (ZIF‑8 and Al‑Fum) following standardized protocols, with centralised characterisation to evaluate reproducibility and identify critical synthesis parameters. First results were presented at EuroMOF 2025.

To support reproducible and transparent reporting, WG1 has led the development of the Material Preparation Information File (MPIF) — a structured, machine‑readable format capturing essential synthesis details. This effort is laying the foundation for a community‑wide standard compatible with databases and machine‑learning tools (more details).

|

| Material Preparation Information File (MPIF) |

WG1 has also strengthened networking by organising the group into Nano, Meso, and Macro teams, facilitating targeted discussions, collaborations, and student exchanges. In parallel, the MOF Universe platform was expanded into a global interactive map of over 400 MOF research groups, enhancing visibility and collaboration across the international community (more details).

WG2 – MOF Processing, Manufacturing, and Upscaling

Working Group 2 addresses the translation of MOFs from powders into functional materials, shapes, and devices. Over the reporting period, WG2 has focused on community building, identifying key challenges in MOF processing, and aligning activities with other WGs.

An early online survey revealed diverse application interests (water treatment, gas separation and storage, energy, and biomedicine) alongside shared challenges such as reproducibility, solvent minimisation, cost, and property retention during shaping. These insights were used during workshops and discussions at major EU4MOFs events, including the 1st Hybrid EU4MOFs Symposium in Bilbao and subsequent meetings in Brussels, Germany and Türkiye.

Looking ahead, WG2 has prioritised engagement with industry partners, standardised protocols, life‑cycle considerations, and hands‑on training through workshops, STSMs, and planned activities on scale‑up and manufacturing.

WG3 – MOF Characterisation and Performance Evaluation

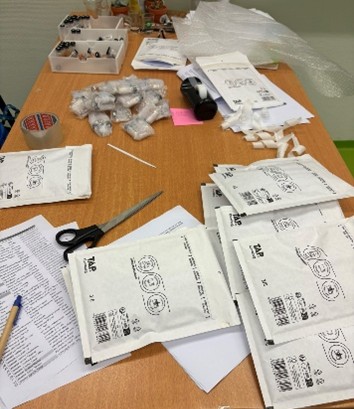

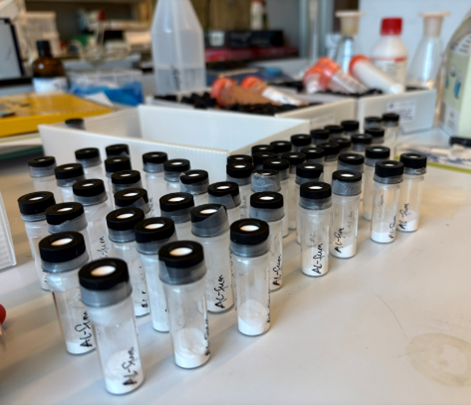

WG3 has played a central role in evaluating MOF reproducibility and performance through coordinated characterisation efforts. In close collaboration with WG1, WG3 contributed to Round Robin Study 1 (RR1) and led Round Robin Study 2 (RR2), which engaged around 40 laboratories worldwide.

|

|

| Preparations for Round Robin Study 2 | |

RR2 focused on benchmarking key characterisation techniques (PXRD, TGA, N₂ sorption, IR, Raman, and ¹H NMR spectroscopy) using three standard MOF samples, with results compared against expert‑defined gold standards. This large‑scale effort provides critical insight into interlaboratory variability and best practices.

WG3 also co‑developed the MPIF alongside WG1, reinforcing links between synthesis, characterisation, and data reporting. Dissemination efforts included promotion of EU4MOFs initiatives and MPIF at international conferences such as EuroMOF2025.

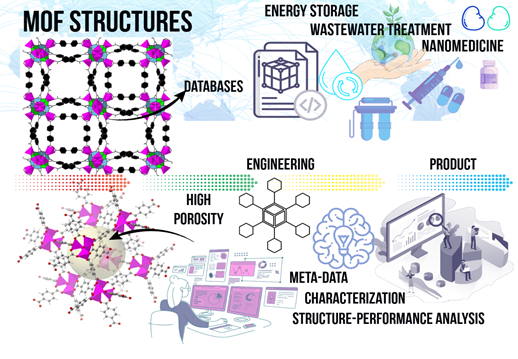

WG4 – Computational Tools and Machine Learning

WG4 focuses on computational screening, modelling, and machine‑learning approaches to understand and optimise MOF properties across length scales. Two major deliverables have already been completed: a training school on computational and AI tools, and a high‑profile perspective on machine learning for porous materials.

|

| WG4 overview |

The Training School on MOF Computational Tools, Machine Learning, and Databases, held in Istanbul in October 2024, trained over 50 researchers through lectures and hands‑on sessions led by leading experts. Topics spanned machine‑learning potentials, adsorption modelling, high‑throughput screening, open data, and AI‑driven materials discovery (more details).

In 2025, WG4 published a collaborative JACS perspective on artificial‑intelligence paradigms for next‑generation MOF research, highlighting the growing role of data‑centric and language‑model‑based tools (more details). Future plans include establishing a standardized, expandable database linking synthesis, properties, and modelling data for key applications.

WG5 – Dissemination, Industrial Networking, and MOF Market Assessment

WG5 has focused on strengthening links between academia and industry and supporting innovation pathways for MOF technologies. Since late 2024, representatives from 18 companies and start‑ups spanning energy storage, water and air purification, and nanomedicine have formally joined the Action.

A flagship activity was the EU4MOFs Meeting: Bringing Academia and Industry Together, co‑organised with WG1 in Kraków (June 2025). The hybrid event combined academic and industrial presentations, student flash talks, speed networking, and round‑table discussions, fostering cross‑sectoral exchange (more details).

WG5 members also collaborated on several competitive funding proposals, including Pathfinder, Water4All, and MSCA Doctoral Network submissions, and contributed to high‑impact publications and conference dissemination, including EuroMOF 2025.

Looking Ahead

Together, the five Working Groups are building a coherent ecosystem connecting synthesis, characterisation, processing, computation, and industry engagement. Key priorities moving forward include finalising and adopting MPIF standards, expanding round robin studies, strengthening data integration and machine learning, supporting early career researchers, and translating MOF research into scalable, sustainable technologies.

In parallel, EU4MOFs will continue to strengthen the link between academia and industry, fostering closer dialogue to enable more optimised, application-driven MOF design and to accelerate industrial adoption. The Action will also expand its network by attracting new research groups working on MOFs and related materials, as well as additional industrial partners, with the long-term vision of establishing a MOF hub that actively promotes collaboration, knowledge exchange, and effective technology transfer.

Through continued collaboration and community engagement, EU4MOFs is well positioned to deliver lasting impact for both fundamental research and real-world applications.